Sigma Institute for Engineers

Why to Choose Sigma institute for Engineers ?

- Batch wise systematic training

- Syllabus designed after vast industrial experience

- Experienced faculties having vast experience

- Carrier guidance at all levels

- Placement assistance at all levels

- Well equipped instrumentation lab

- More PLCs for practice

- Chance to work on live panel work

- Learning by industrial examples

- Its more than only learning

- Limited student in batch

- Personal attention to each student

- Engineering books and magazines for more knowledge

No Other Institute has Syllabus like we have

A BRIDGE BETWEEN COLLEGE AND CAREER ……AND WAY TO IIoT (INDUSTRIAL INTERNET OF THINGS) & INDUSTRY 4.0

Syllabus

Panel door controls :

Switches :

Push button with NO/NC contacts, selector switches, spring return selector, Toggle and rocker switches, Illuminated pushbuttons, push to ON push to OFF, Mushroom headed switch etc.

Panel door indicators:

Bulb indicator, LED indicator, Bacon, hooters, buzzers, panel meters and tower light etc.

Sensors :

Position :

Limit switches, inductive-capacitive-magnetic-optical-ultrasonic proximity switches, shaft encoder, liner encoder, LVDT, linear potentiometer etc.

Temperature :

RTD (PT100), Thermocouple, Thermistor, Pyrometer, thermostat, Semiconductor temperature sensor, temperature transmitters, thermowell, Temperature controllers etc.

Pressure :

Pressure transmitter, pressure switch, pressure gauge etc.

Flow :

Paddle wheel, target, Rotameter, differential pressure, positive displacement, velocity, mass and open channel etc.

Level :

Vibrating fork, conductivity probe, capacitive, ultrasonic etc.

Actuators :

Relay, contactor, solenoid and solenoid valves, SSR, PPC SSR, stepper and servo motors, pneumatics, vacuum, hydraulics etc.

Safety :

Human Safety Devices :

Helmet, Gloves, Safety shoes, Goggles, Nose mask, Ear Plugs, Boiler Suit, Scaffold, Safety lamp etc.

Machine Safety Devices :

Fuse, SFU, MCB, MCCB, RCCB/ELCB, Earthing, OLR, MPCB, MPD, Ingress Protection (IP), Hazardous area classification, intrinsic safety and signal Isolation etc.

Accessories :

PVC channel, DIN rail, lugs, cable marking ferrules, sleeves, terminal block connectors, tb marker, 22.5 mm blind, end clamp, end plate, cable gland, document holder, spiral bind, cable tie & tie base, air vent (filter), cooling fan, name plate, panel lock, hinges pcb supporter & spacer, busbar, busbar insulator or supporter, cable tray, conduit cable and wires, control transformer, binding belt, lacing cord, utility socket etc.

Wiring exposure :

Jog, DOL starter, RDOL starter, YD starter, interlocking, holding, dependency, sensor Interfacing etc.

PLC :

PLR, micro and modular PLCs, Siemens S7-200 and S7-300, Mitsubishi FX and A Series, Omron CP1E, Allen Bradley Micrologix 1100 & 1400, Schneider Zelio, Vipa, Teco etc.

HMI :

Siemens TP177, OP77B, TD200, Omron NB5Q, Baijer E700, Kinco MT4434TE etc.

SCADA :

Citect, Wonderware Intouch, Siemens WinCC Flexi etc.

VFD :

Siemens MM440 with encoder feedback, Yaskawa V1000 etc.

IIoT Devices :

Modbus to MQTT Converter, ESP32 based IIoT Interface, Ethernet to WiFi converter, Rs485 to Ethernet converter, WiFi router

Mechatronics :

CNC router, 3D printer, Lead screw mechanism, Stepper and servo motion control

ADIA Advanced Diploma in Industrial Automation = Module I + Module II + Module III

Module I

EIA (Essentials of Industrial Automation)

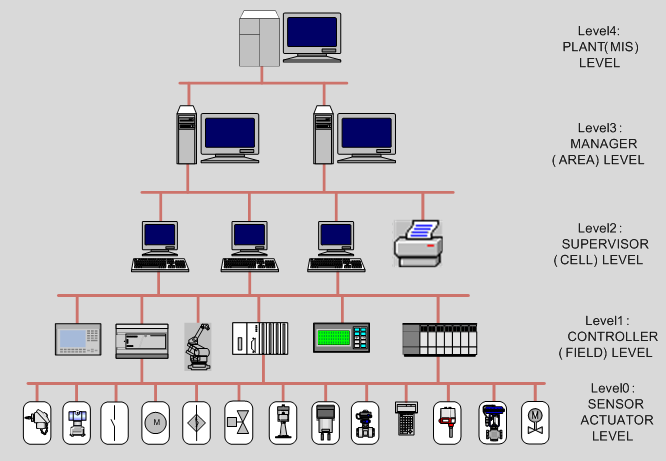

- Topic I : Industrial Automation – An overview

- Topic II : Electrical Concepts

- Topic III : Panel door controls and indicators

- Topic IV : Sensors

- Topic V : Actuators

- Topic VI : Controllers

- Topic VII : Industrial safety and related devices

- Topic VIII : Panel and field accessories

- Topic IX : Industrial documentation

- Topic X : Industrial panel wiring

- Topic XI : Use of tools and multimeter

Module II

PLC Essentials of Programmable Logic Controller

- Topic I : Types of industrial processes and their control mechanisms

- Topic II : Concept of PLC

- Topic III : Introduction to PLC hardware

- Topic IV : Introduction to offline simulator software, ladder diagram and IEC61131-3

- Topic V : Basic Instruction sets

- Topic VI : Introduction to online simulator software and ladder writing

- Topic VII : Data handling instruction sets

- Topic VIII : Analog signal processing

- Topic IX : Introduction to various make PLCs and their respective software

- Topic X : Introduction to advanced programming

- Topic XI : Selection of PLC

- Topic XII : PLC installation and wiring

- Topic XIII : PLC testing, commissioning and troubleshooting

Module III:

AIA Advanced Industrial Automation

- Topic I : Basics of SCADA, creating new SCADA applications, tag generation, screen development, Buttons, numeric display and input, animated object, trends, report, alarm, SCADA communication and protocols etc.

- Topic II : HMI Basics and types of HMI, creating new HMI program, tag generation, screen development, buttons, numeric display and input, alarm, HMI communication and protocols etc.

- Topic III : AC Drives: Fundamentals, parameter settings, open loop and close loop speed controls etc.

- Topic IV : PID Controls : concept and practical implementation using PLC

- Topic V : Concepts of IIoT and Industry 4.0

Advance Module for Industrial Automation = Module IV, Module V, Module VI

Module IV:

APP Advanced PLC Programming

- Topic I : Introduction to basic instructions

- Topic II : Program control instructions

- Topic III : Interrupts

- Topic IV : High Speed Counting (HSC) and Pulse Output (PTO)

- Topic V : Advanced instructions for PLC programming

- Topic VI : PID instructions

- Topic VII : Applied techniques for programming and trouble shooting

Module V:

ED Electrical Drafting

- Topic I : Introduction

- Topic II : Introduction to CAD software

- Topic III : Introduction to symbols

- Topic IV : Electrical drafting

- Topic V : Maintaining documentation

- Topic I : Panel definition and need of panel

- Topic II : Types of panels

- Topic III : Basics of panel components

- Topic IV : Making of different types of control and power circuits with simulation

- Topic V : Panel Documentation

- Topic VI : Concepts of panel designing

- Topic VII : Use of tools

- Topic VIII : Panel installation and maintenance

- Topic IX : Workflow of panel designing

- Topic X : Practical panel wiring

- Topic XI : Intelligent MCC

- Topic XII : Industrial Visit

Also available :

- Embedded Applications (8051 µC)

- Robotics Applications

- Customized training for corporate clients

- Customized training for educational institutes

- Project training for engineering students